The

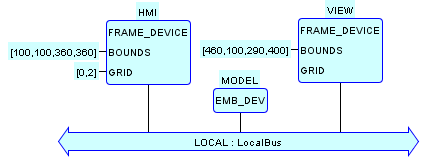

VIEW

device is configured identically as in the TESTBED_VIEWL

configuration.Click on a Device to view its configuration.

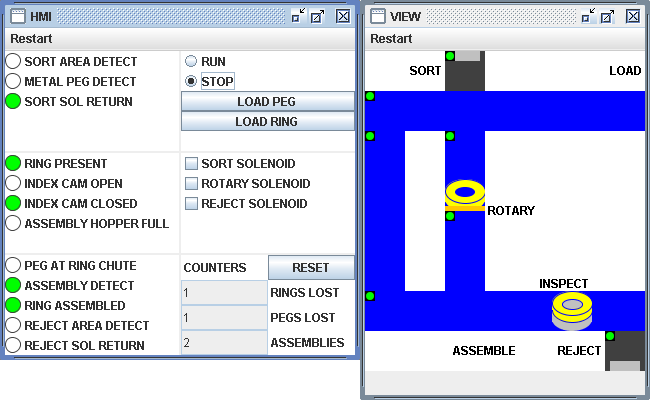

The

HMI

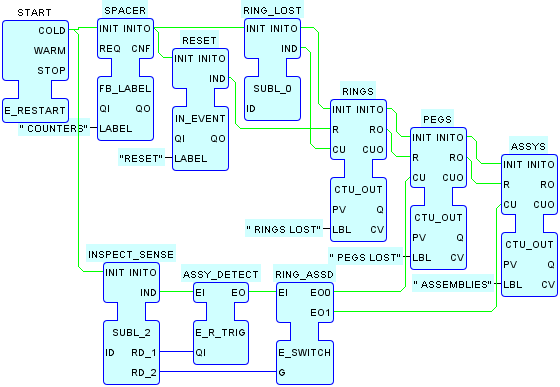

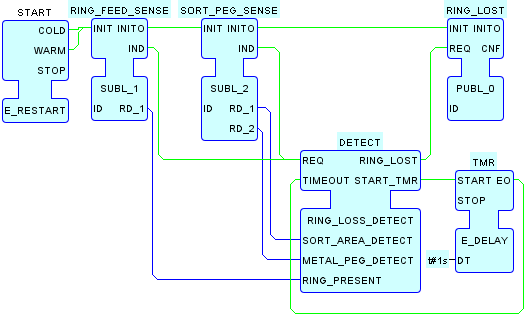

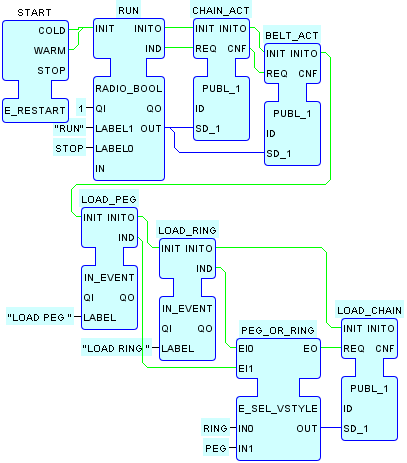

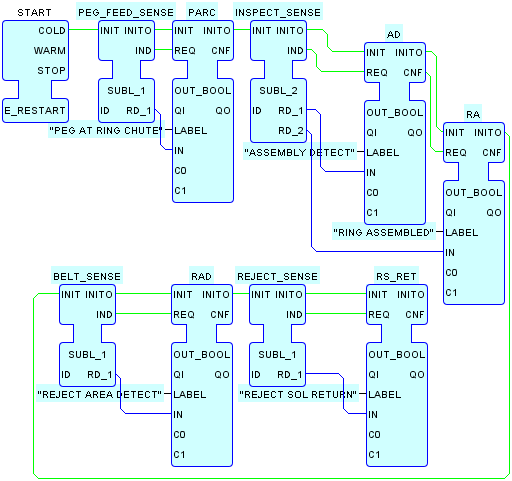

device encapsulates the functionality of the HMI layer of the

architecture, including the HMI elements needed to:

- read sensor values;

- simulate manual loading of pegs and rings to the chain conveyor;

- write actuator values; and

- maintain resettable counts of "lost" (unassembled) rings and pegs and of peg/ring assemblies produced.

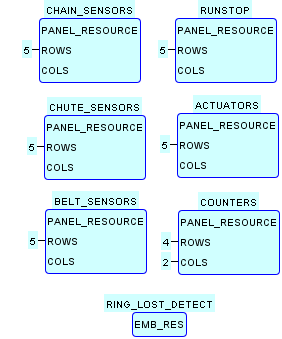

The

MODEL

device contains eight instances of the EMB_RES

type, which in turn contain the Model elements for the

corresponding Views, as well as logic to simulate the physics

of the interactions among Model elements including their

sensors and actuators and transfer of workpieces.

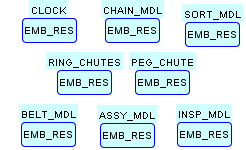

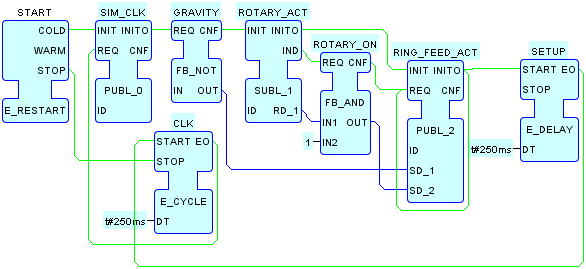

The

CLOCK

resource contains the simulation clock, whose events are distributed

using the local

multicast pattern. It also contains additional logic to provide

"artificial gravity", i.e., a constant ON signal to the "motors" of

the chutes in the PEG_CHUTE

and RING_CHUTES resources.

The

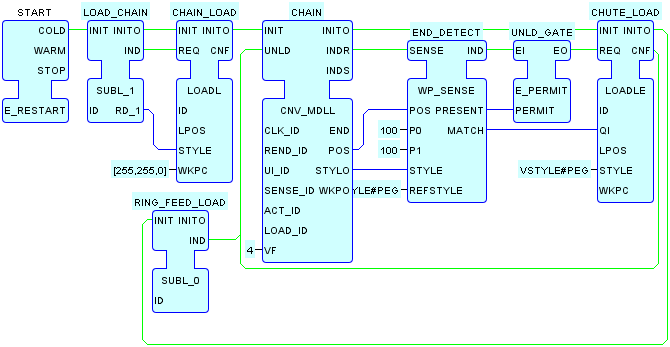

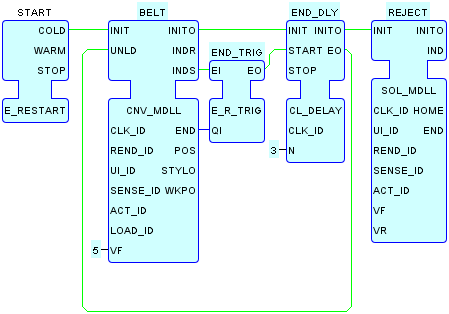

CHAIN_MDL

resource contains an instance of the CNV_MDLL type,

corresponding to the chain in the CHAIN

view.

The

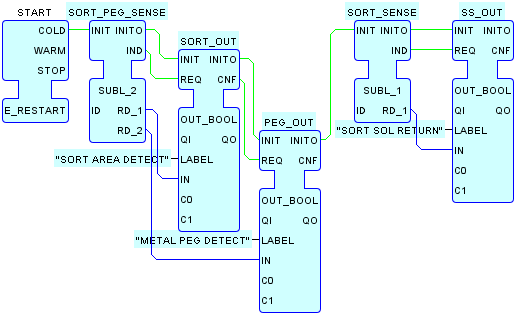

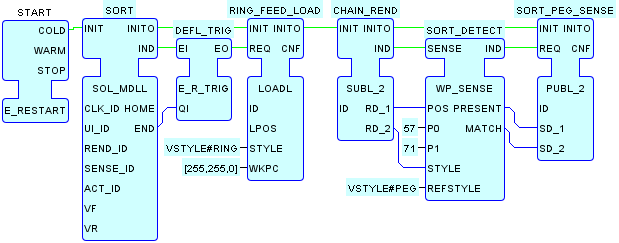

SORT_MDL

resource contains an instance of the SOL_MDLL type,

corresponding to the sorter solenoid in the

CHAIN

view.

The

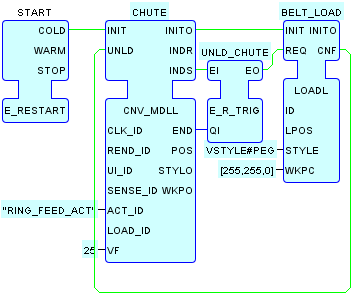

PEG_CHUTE

resource contains an instance of the CNV_MDLL type,

corresponding to the

CHUTE

element of the

CHUTES

view.

The

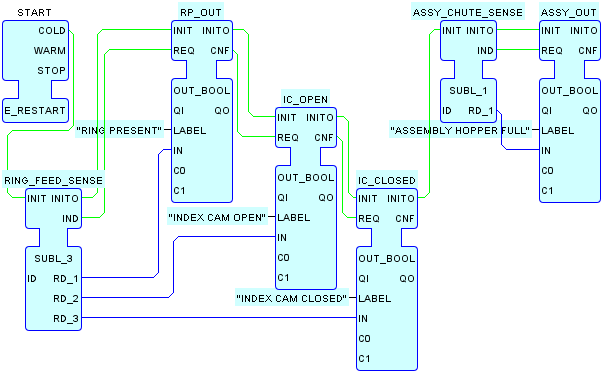

RING_CHUTES

resource contains instances of the CNV_MDLL

type, corresponding to the

CHUTE

element of the

CHUTES

view.

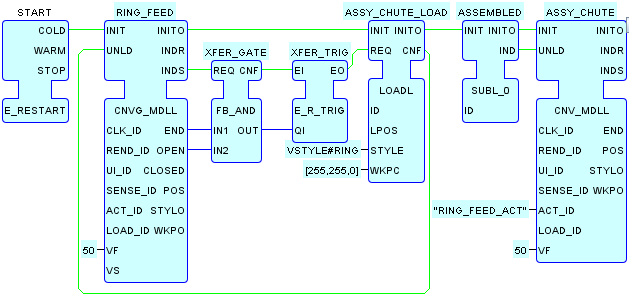

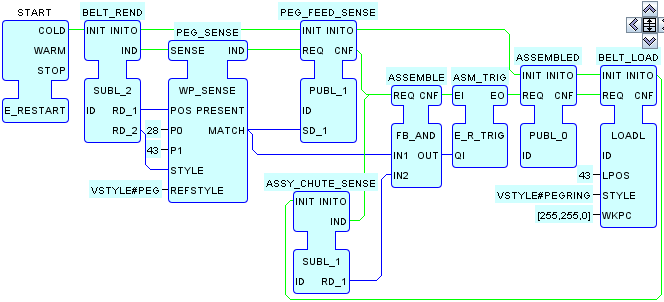

The

BELT_MDL

resource contains intances of the CNV_MDLL

and CNVG_MDLL

types, corresponding to the

ASSY_CHUTE

and

RING_FEED

elements of the

CHUTES

view, respectively.

The

ASSY_MDL

resource models the peg/ring assembly.

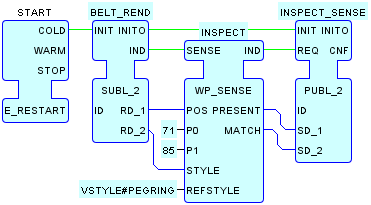

The

INSP_MDL

resource uses an instance of the WP_SENSE

type to model the operation of the inspection station.

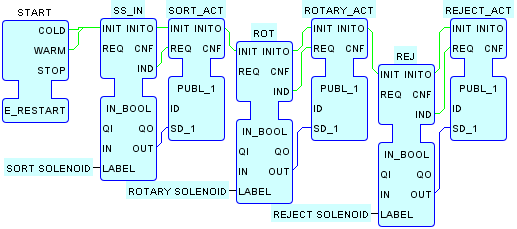

Inter- and intra-layer communication is implemented with the local multicast

pattern, in particular for the distribution of the simulation clock

and the simulation of workpiece transfer with instances of the LOADL and LOADLE types. The FBDK

uses the Tagged Data

design pattern to ensure consistency of the communicated events and

data, as shown in the table below.

Where applicable, this table lists the correspondences between the tag names and the testbed's Sensor/Actuator labels, which are also used in the HMI.

| Name | Type | UDP Channel | Description |

|---|---|---|---|

ASSEMBLED |

|

|

MODEL Internal Peg/Ring Assembly Event |

ASSY_CHUTE_SENSE |

BOOL |

|

ASSEMBLY HOPPER FULL |

BELT_ACT |

BOOL |

|

BELT CONVEYOR |

BELT_REND |

UINT,VSTYLE |

|

MODEL/VIEW Internal Belt Position + Workpiece

Style |

BELT_SENSE |

BOOL |

|

REJECT AREA DETECT |

CHAIN_ACT |

BOOL |

|

CHAIN CONVEYOR |

CHAIN_REND |

UINT,VSTYLE |

|

MODEL/VIEW internal chain position +

workpiece style |

INSPECT_SENSE |

BOOL,BOOL |

|

ASSEMBLY DETECT, RING ASSEMBLED |

LOAD_CHAIN |

VSTYLE |

|

Load chain with VSTYLE workpiece |

PEG_FEED_SENSE |

BOOL |

|

PEG AT RING CHUTE |

REJECT_ACT |

BOOL |

|

REJECT SOLENOID: 1=Advance, 0=Retract |

REJECT_SENSE |

BOOL |

|

REJECT SOL RETURN |

RING_FEED_ACT |

BOOL,BOOL |

|

MODEL internal (TRUE, ROTARY SOLENOID) |

RING_FEED_LOAD |

|

|

MODEL internal chain to chute ring transfer

event |

RING_FEED_SENSE |

BOOL,BOOL,BOOL |

|

RING PRESENT, INDEX CAM OPEN,

INDEX CAM CLOSED |

RING_LOST |

|

|

HMI Internal: Ring passed by chute, discarded |

ROTARY_ACT |

BOOL |

|

ROTARY SOLENOID: 1=Advance, 0=Retract |

SIM_CLK |

|

|

MODEL simulation clock |

SORT_ACT |

BOOL |

|

SORT SOLENOID: 1=Advance, 0=Retract |

SORT_PEG_SENSE |

BOOL,BOOL |

|

SORT AREA DETECT, METAL PEG DETECT |

SORT_SENSE |

BOOL |

|

SORT SOL RETURN |